Structural Bearings

ESPT offers design, supply, manufacturing, and installation of CE-marked European-approved spherical and POT bearings, featuring special sliding materials for temperatures up to +90 degrees Celsius.

Bridge Bearing Information

About Bridge Bearing

Bridge bearings are essential components in bridge construction, designed to facilitate movement and transfer loads between the bridge's superstructure (deck) and substructure (piers or abutments).

Functions of Bridge Bearings

- Load Transmission: Bearings transfer vertical loads from the bridge deck to the supporting structure. They also handle dynamic forces like wind, traffic, and seismic activity.

- Movement Accommodation: Bearings allow controlled movement due to thermal expansion, contraction, and shrinkage of materials. They also accommodate rotational movements caused by changes in alignment or external forces.

- Vibration Isolation: Some bearings are designed to dampen vibrations, improving the bridge's stability and longevity.

Types of Bridge Bearings

- Elastomeric Bearings: Made of rubber, these bearings allow movement through elastic deformation. They are cost-effective and require minimal maintenance.

- Sliding Bearings: These bearings have flat or spherical sliding surfaces to allow horizontal and rotational movement. Modern sliding bearings often use materials like Teflon for smooth operation.

- Rocker Bearings: Rocker bearings have curved surfaces that allow rocking motion, accommodating horizontal movement.

- Fixed Bearings: These bearings allow rotation but restrict other forms of movement, providing stability.

- Mechanical Bearings: Includes types like roller bearings and pinned bearings, which are used for specific structural requirements.

Sliding Material

Sliding materials are specialized substances designed to reduce friction and wear in applications where surfaces move against each other. They are widely used in industries like manufacturing, automation, and transportation.

Key Characteristics

- Low Friction: Sliding materials are engineered to have a low coefficient of friction, ensuring smooth movement and reducing energy loss.

- Wear Resistance: These materials are durable and can withstand repeated use without significant degradation.

- Chemical Resistance: Many sliding materials are resistant to chemicals, making them suitable for harsh environments.

- Noise Reduction: Some materials are designed to minimize noise during operation, which is crucial in applications like conveyor systems.

Common Types

- Plastics: Materials like PTFE (Teflon), POM (Polyoxymethylene), and UHMWPE (Ultra-High-Molecular-Weight Polyethylene) are popular for their low friction and wear resistance.

- Metals: Bronze and certain steel alloys are used in heavy-duty applications due to their strength and durability.

- Composites: Advanced composites combine the benefits of multiple materials, offering tailored properties for specific applications.

Sliding Materials for Bearings

- Fluoropolymers (e.g., PTFE): Known for their low friction and excellent wear resistance. Commonly used in spherical and cylindrical bearings for bridges and structural applications.

- High-Strength Composites: Materials like SMS are engineered for exceptional strength and durability. These composites are often used in bearings for structures requiring large sliding movements, such as suspension bridges.

- Advanced Steel Alloys: Special Fe-C-N composite materials are heat-treated for high wear resistance and durability. These materials are suitable for applications requiring high load-bearing capacity and corrosion resistance.

Installation

The placement of bridge bearings is a critical step in bridge construction, ensuring proper load transfer and accommodating movements.

Placement Guidelines

- Preparation: The bearing area on the substructure (piers or abutments) must be leveled and cleaned to ensure a smooth surface. A bedding layer, often made of mortar or neoprene pads, is applied to provide uniform support.

- Alignment: Bearings must be precisely aligned to match the design specifications, ensuring they can accommodate movements like expansion, contraction, and rotation. Misalignment can lead to uneven load distribution and premature wear.

- Fixing: Bearings are secured to the substructure using bolts, dowels, or adhesive materials, depending on the type of bearing. For sliding bearings, the sliding surface is treated to minimize friction.

- Testing: After placement, bearings are tested for functionality, including their ability to handle loads and movements.

- Maintenance Access: Bearings should be placed in a way that allows easy access for inspection and maintenance.

Bearing Replacement

Bridge bearing replacement is a complex process that involves removing old or damaged bearings and installing new ones to restore the bridge's functionality and safety.

Steps in Bridge Bearing Replacement

- Inspection and Assessment: Engineers inspect the existing bearings to determine the extent of wear or damage. They assess the bridge's structural condition to plan the replacement process.

- Bridge Jacking: Hydraulic jacks are used to lift the bridge deck slightly, relieving pressure on the bearings. This step requires careful monitoring to avoid structural damage.

- Removal of Old Bearings: The damaged bearings are carefully removed, ensuring minimal disruption to the surrounding structure.

- Installation of New Bearings: New bearings are aligned and installed according to design specifications. Proper alignment is crucial for accommodating movements and transferring loads effectively.

- Testing and Final Adjustments: The new bearings are tested for functionality, including their ability to handle loads and movements. Engineers make final adjustments to ensure optimal performance.

Challenges

- Safety: Lifting the bridge deck requires precise control to prevent accidents.

- Access: Bearings in hard-to-reach areas may require specialized equipment.

- Environmental Factors: Weather conditions can impact the replacement process.

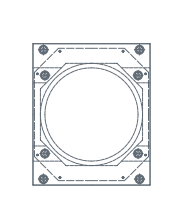

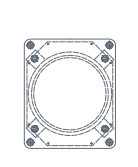

Spherical Bearings

Spherical bearings consist of a convex spherical calotte with a sliding material that mates with a spherical sliding element. They can be combined with flat sliding elements and guides to form free and guided bearings, or with a restraining ring for fixed bearings. These bearings are ideal for structures with medium to high loads and limited installation heights, absorbing large rotations in all directions.

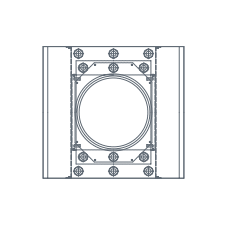

POT Bearings

POT bearings accommodate differential movements in various structures, especially in bridge engineering. They handle vibrations, movements, and rotations caused by earthquakes, traffic loads, or climatic conditions while protecting the structure from damage.

Suitable for transmitting vertical loads from zero to over 100,000 kN.

Free Movable

Fixed

Guided

Free Movable

Fixed