Threaded Bars

Explore our range of threaded bars designed for various construction applications. Find detailed specifications and benefits of our threaded bars below.

WS Type Plain Bars

- •Diameter: 26-40 mm

- •Cold Rolled Thread on Either Side with Low Slip Special Slip

- •WS Bar Tendons for Short Lengths < 2.5 m

- •WR Bar Tendons for Lengths > 2.5 m

WR Type Threaded Bars

- •Diameter: 18-75 mm

- •Continuous Hot-Rolled Thread

- •Can Be Divided and Coupled in Any Section

- •Constant Young's Modulus with Factory-Controlled Elongation of the Thread Bar Steel

- •Continuous Quality Inspection and Control

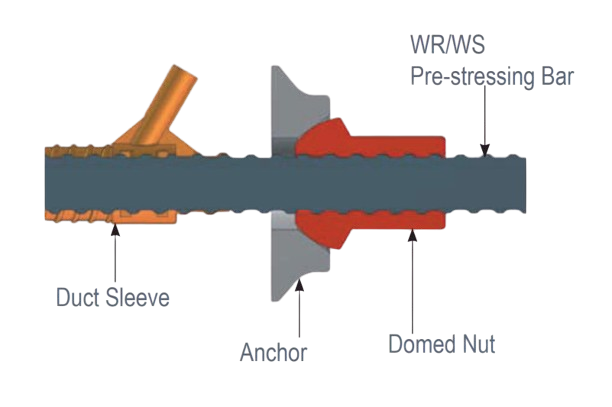

Stressing Anchorage, Bonded

This bar is secured with a domed anchor nut and a retaining nut to the anchorage plate, which is then fixed to the scaffolding. The retaining nut connects to the duct, and grouting is performed through the grout cap, the domed anchor nut with three grout slots, and the retaining nut.

Fixed Anchorage, Bonded

The fixed anchorage is largely embedded in the concrete. The domed anchor nut is tack-welded perpendicularly onto the anchor plate. The duct sleeve ends directly at the anchor plate where the duct is injected or vented. A fixed anchorage can also function as a stressing anchorage, eliminating the need for bar-over length for stressing.

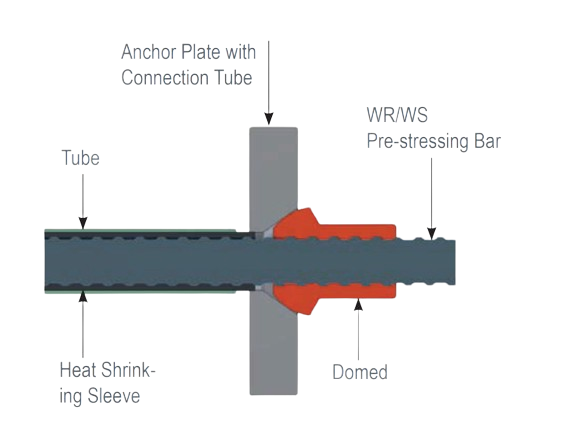

Stressing Anchorage, Unbonded

A connection tube is welded to the anchor plate to bridge the gap behind it, preventing water intrusion into the anchorage region.

Fixed Anchorage, Unbonded

The fixed anchorage is mostly embedded in the concrete. The domed anchor nut is tack-welded perpendicularly onto the anchor plate, and the prestressing bar is provided with appropriate corrosion protection.