ESPT Offers an Integrated Service, from Anchor and Floor Design to Production and Installation

- Achievement of complex geometry & special design challenges – meeting all the needs of modern architecture.

- Large column-free spaces – spans of up to 15m are common in standard PT slabs.

- Shallower slabs – PT slabs are up to 30% shallower, reducing the building height or allowing more floors within the original building height.

- Less materials – with PT, less concrete and steel is needed for the superstructure.

- Program & cost saving – groundwork requirements for a PT structure are reduced.

- Faster program – thinner PT slabs and early strength stressing, promoting faster floor cycle times.

- Reduced maintenance costs – structures are more durable as use of PT promotes better crack and deflection/vibration control.

Prestressing by Post-Tensioning in the Building Sector

- •Contemporary architectural trends favor large uninterrupted floor areas and flexible internal layouts that are easy to modify and move around in, while being fundamentally durable and functional. These multiple requirements can be met through prestressing by post-tensioning, which allows for large unobstructed spans with a minimum number of columns and reduced floor thickness.

- •The prestressing systems can be used in floors, foundation slabs, and building transfer structures. They are a cost-effective, reliable solution for optimizing a wide range of structures.

Internal Bonded Post-Tensioning Internal and External

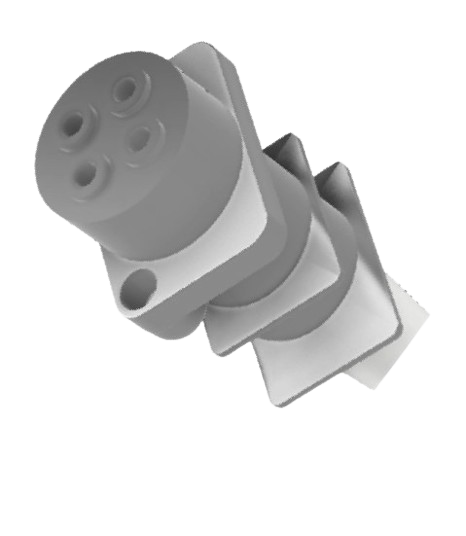

Bonded post-tensioning slab system consists of fully encapsulated, bonded multi-strand (two to five strands) tendons contained in flat ducts filled with a high-performance cementitious grout that bonds the strands to the surrounding concrete.

When the tendons have stretched sufficiently, according to the design specifications, they are wedged in position and maintain tension after the jacks are removed, transferring pressure to the concrete. The duct is then grouted to protect the tendons from corrosion.

Un-Bonded Post-Tensioning Internal and External

Adaptable to a variety of structures, un-bonded mono-strand post-tensioning can be easily, rapidly, and economically installed. Uses 0.5” and 0.6” diameter strands coated with a layer of specially formulated grease with an outer layer of seamless plastic extruded in one continuous operation to provide protection against corrosion. Each tendon is precisely coiled, cut, labeled, color-coded, and delivered to the construction site.

Benefits of Post-Tensioning in Buildings

- •Achievement of complex geometry & special design challenges – meeting all the needs of modern architecture.

- •Large column-free spaces – spans of up to 15m are common in standard PT slabs.

- •Shallower slabs – PT slabs are up to 30% shallower, reducing the building height or allowing more floors within the original building height.

- •Less materials – with PT, less concrete and steel are needed for the superstructure.

- •Program & cost saving – groundwork requirements for a PT structure are reduced.

- •Faster program – thinner PT slabs and early strength stressing, promoting faster floor cycle times.

- •Reduced maintenance costs – structures are more durable as use of PT promotes better crack and deflection/vibration control.